CMI researchers at Oak Ridge National Laboratory and Idaho National Laboratory conducted the activity for this highlight

Innovation

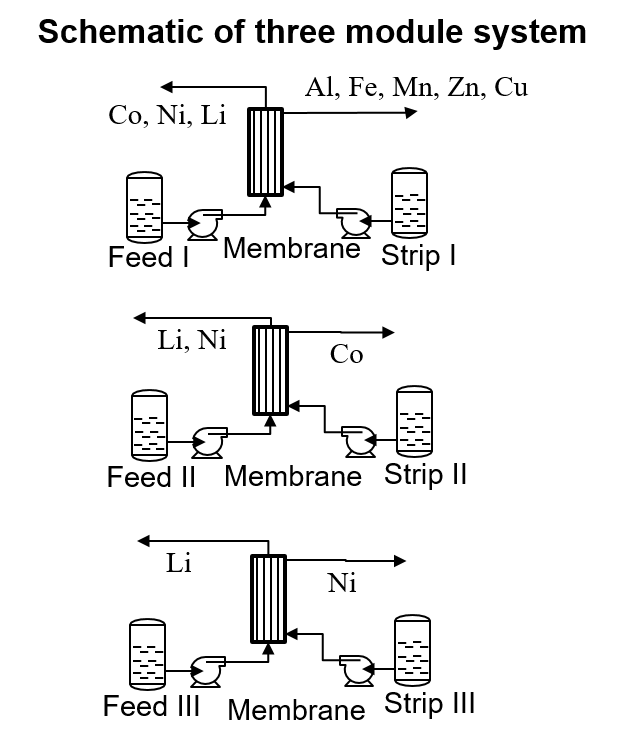

Improved continuous process for LIB metal recovery

Achievement

- Demonstrated integration of additional Membrane Solvent Extraction (MSX) module for removal of Al, Fe, Mn, Zn and Cu in a single stage prior to MSX recovery of Co and Ni (two separate modules).

- Battery materials were recovered with a 99 - 99.99 wt.% purity required for remanufacturing of electric vehicle (EV) batteries.

Significance and Impact

- Separation of battery materials from black mass is challenging due to complexity and diversity of sources.

- Ability to implement additional modules for targeted separations in continuous in-line system provides robustness. Removal of all impurities in a single stage improves process efficiency.

Hub Goals Addressed

Win industry adoption of one technology related to recycling or reuse for lithium and cobalt