CMI researchers at Oak Ridge National Laboratory conducted the research for this highlight

Achievement

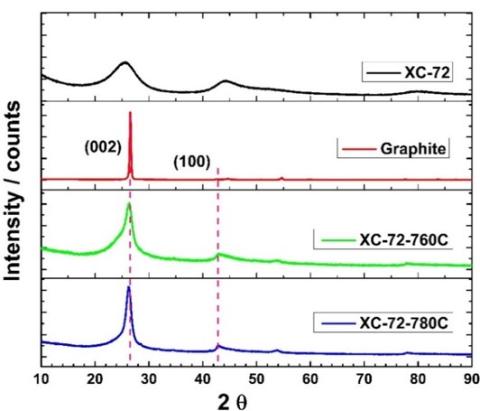

Electrochemical graphitization of amorphous carbon at 760 °C with >75% graphitization has been achieved in ternary eutectic molten salts.

Significance and impact

- Energy savings of 90%, cost savings of 50% vs Acheson industrial synthesis.

- Produces high-quality graphite for battery anodes without further treatment.

- Applicable to different carbon feedstocks.

- Potential to replace current technology.

- Accelerates synthesis from weeks to hours.

- Potential to reduce imports of natural graphite.

Details and next steps

Understand the melt chemistry associated with ternary eutectic molten salts and details of graphitic transformation. Learn how to increase batch size at lab scale. Optimize the technology for industrial adoption.