CMI researchers at Colorado School of Mines lead the activity for this highlight

Innovation

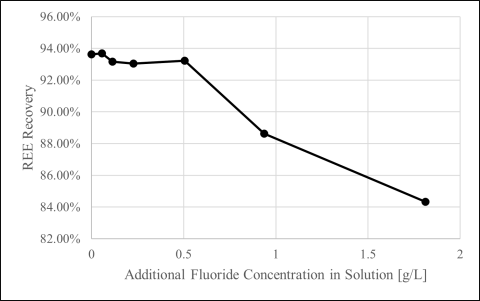

Development of a process flowsheet achieving 80% REE recovery from bastnaesite, a domestically abundant REE fluorocarbonate mineral, (La,Ce)CO3F, while mitigating fluoride’s negative effects (Fig. 1).

Achievements

- Improved REE recovery to >90% using a high-temperature HCl leach of bastnaesite without REE fluoride precipitation.

- Successfully extracted >95% of REEs from solution using TODGA extractant, while stripping >90% of REEs from the loaded solvent.

- Removed fluoride from the extracted leachate by use of activated alumina so that the high HCl solution could be recycled without fluoride interference (Fig. 2).

Significance and Impact

Increases yield of REE in domestic mining and lowers costs and energy consumption by avoiding a separate roast-leach flowsheet for (REE)F3.

Hub Target Addressed

Highly selective separation from complex sources. Development of technological options that assure supply chains of materials.

Patent Pending