CMI at Idaho National Laboratory conducted the activity for this highlight

Innovation

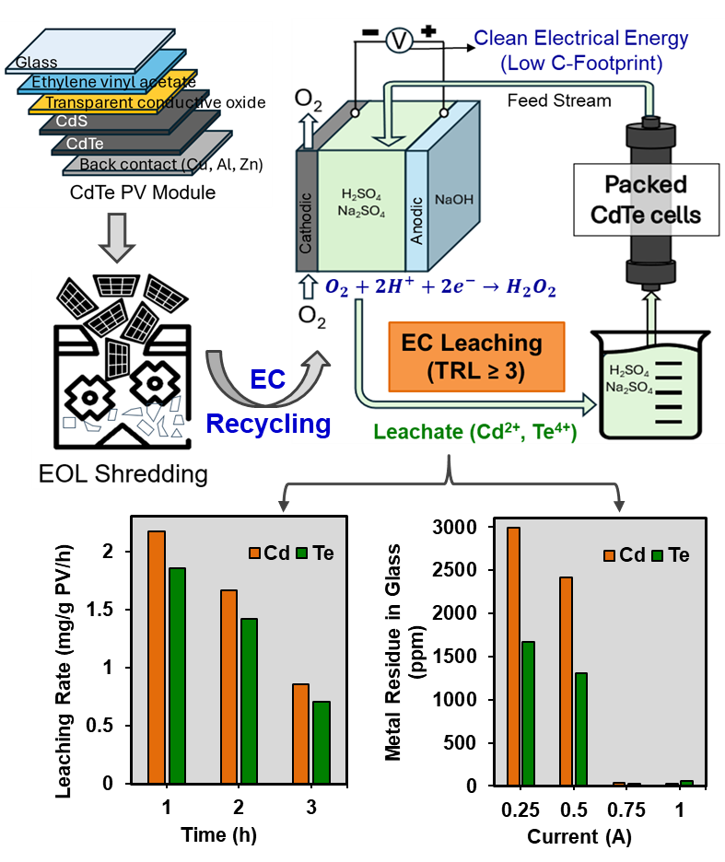

A novel benchtop-scale electrochemical leaching (ECL) technology recovers Te and Cd from CdTe PV solar panels with efficiency and performance superior to traditional chemical leaching (CL).

Achievement

- ECL offers >99% extraction efficiencies for Te and Cd, surpassing CL’s 90%, and works at lower temperature (25 vs. 70 °C) and ~10-fold faster.

- ECL precludes the need of external H₂O₂ by 40 kg per ton PV and cuts H₂SO₄ and alkali needs 8-fold.

- ECL produces cleaner glass byproduct (Cd residue 25 vs 200 ppm).

Significance and Impact

Higher yield, faster operation, cleaner byproducts, and reduced chemical use and waste generation will improve cost and sustainability of Te recovery.

Hub Target Addressed

Minimizing hazardous chemical use and waste generation.