CMI researchers from Idaho National Laboratory and University of Texas Rio Grande Valley conducted the activity for this highlight

Innovation

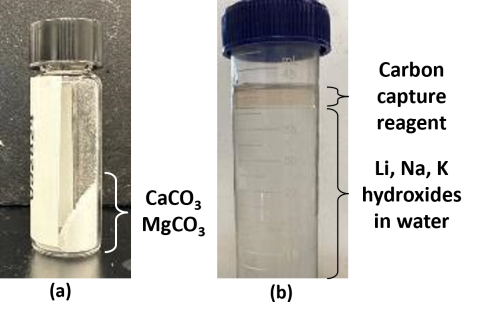

A two-step lithium recovery method separates and concentrates lithium from brine sources. Carbon dioxide captured by a recyclable agent is used to mineralize divalent metal ions and remove them from solution, and electrodialysis further purifies and concentrates the Li.

Achievement

- >80% of lithium is recovered from brine surrogate solutions.

- >99% of divalent metal ions are precipitated as carbonate salts.

- >75% of the reagent used for CO2 capture is recycled.

- A patent based on this technology has been elected.

Significance and Impact

- Development of sustainable lithium recovery technology applicable to domestic resources.

- Use of greenhouse gas, CO2, to mineralize Ca2+ and Mg2+.

- Next step: Development of improved electrodialysis membranes for Li purification.

Hub Target Addressed

Recovery or purification processes to expand U.S. lithium production.

Metal carbonates (e.g., CaCO3)

Reagent for CO2 capture (upper phase) and concentrated LiOH with NaOH and KOH in the lower aqueous phase.