CMI scientists at Ames Laboratory, Lawrence Livermore National Laboratory, Oak Ridge National Laboratory and Eck Industries Inc. contributed to this research.

Achievement:

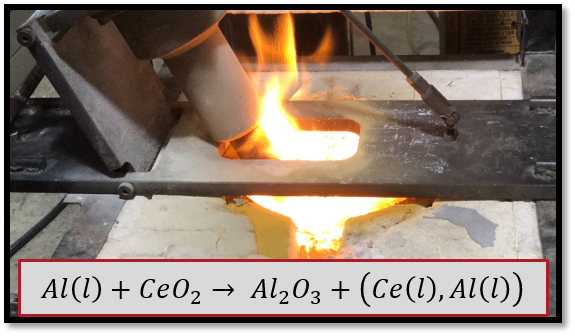

Successful manufacturing demonstration of the production of Al-Ce alloy using direct reduction of commercial-grade cerium carbonate and oxide

Significance and Impact:

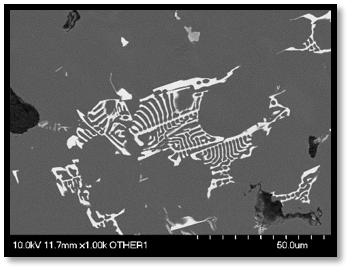

- Preferred Al-Ce alloy micro-structure and mechanical properties are preserved upon adding low-cost Ce carbonate or oxide to the Al melt

- This by-passes a separate Ce reduction step in the supply chain

- Al-Ce alloy cost using Ce oxide or carbonate drops 30–70%, near cost parity with Al metal itself

Next Steps:

- Understand cerium oxide agglomeration and how to achieve complete reduction

- Understand the role of other components such as magnesium in the reaction

- Extend the direct reduction to die casting under flow conditions