CMI researchers from Idaho National Laboratory conducted the research for this highlight.

Innovation

Developed improved metal recycling process by combining biolixiviant production with bioleaching.

Achievement

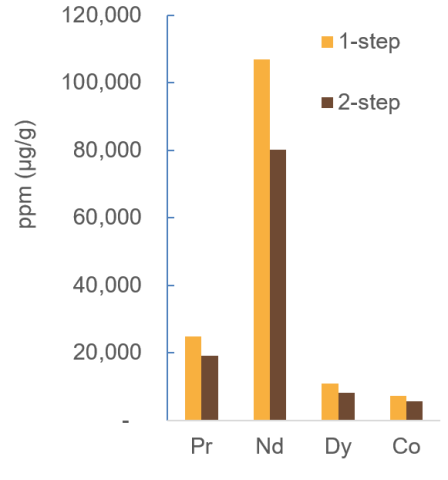

Simultaneous production of biolixiviant from municipal solid waste (MSW) non-recyclable paper (NP) with bioleaching of magnet swarf improved metal recovery by 30% (Fig. 1).

Significance and Impact

- Simultaneous biolixiviant production and bioleaching can decrease capital and operation costs.

- Metal recovery increases and new parameter conditions will be evaluated by technoeconomic and life cycle analyses models to determine the economic and environmental impacts of the new process.

Hub Target Addressed

Sustainable REE recycling from industrial wastes.