CMI researchers from Ames National Laboratory conducted the activity for this highlight

Innovation

An in-house computational tool has been developed for motor design, enabling the comparison of performance between magnets with non-critical and critical elements.

Achievement

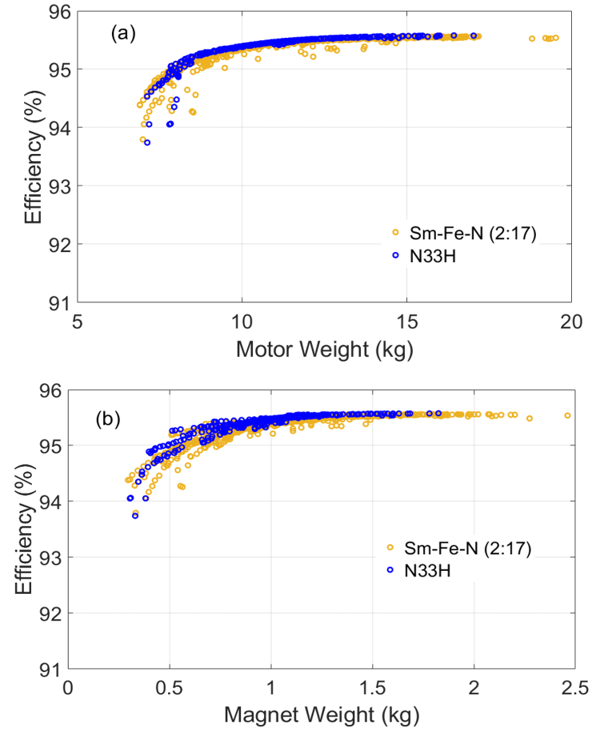

- The tool enables identification of the designs that optimize the performance of alternative magnets in motors.

- With the tool, we showed that Sm-Fe-N (2:17) magnets can replace Nd-Fe-B (N33H) without performance loss and while retaining the motor weight and sizes.

Significance and impact

Development of such a computation tool is an essential step towards accelerating the development of substitutes for critical rare-earth magnets.

Hub Goal Addressed

Prototyping of critical REE-free permanent magnets.