CMI researchers from Ames National Laboratory and Lawrence Livermore National Laboratory conducted the research for this highlight.

Innovation

Lanmodulin (LanM) enables single-stage Dy upgrade from mixed rare earth oxides (REO).

Achievement

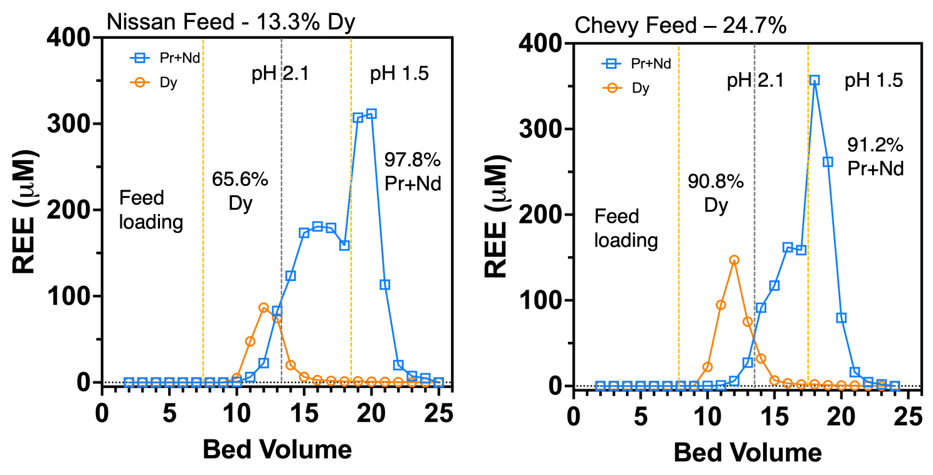

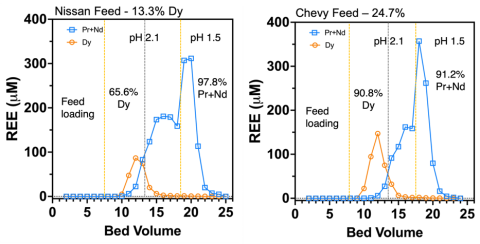

Upgraded Dy content from mixed REO prepared from Nissan Leaf and Chevy Volt motors using Acid-free Dissolution Recycling (ADR) process (FA 3.3.13). In a single adsorption/desorption cycle, Dy content upgraded from 13% to 66% with Nissan sample and 25% to 91% with Chevy sample.

Significance and Impact

- Demonstrated potential to link ADR and bio-based separation processes, meaning that a larger fraction of REE production flow sheet can use environmentally friendly approaches.

- Anticipate that a second column step could further upgrade Dy content to 99+% purity.

Hub Target Addressed

Sustainable method for REE recycling from end-of-life consumer products.