CMI researchers from Oak Ridge National Laboratory and Ames National Laboratory conducted the activity for this highlight

Achievement

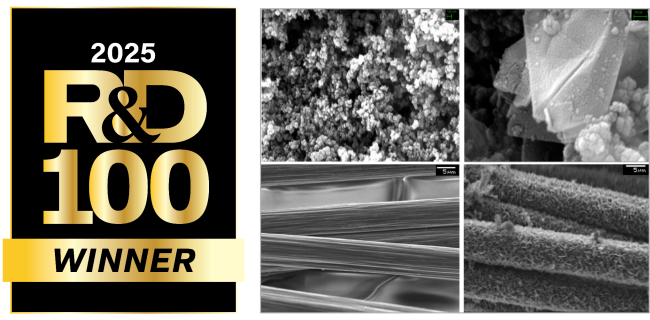

The Critical Materials Innovation Hub’s novel graphitization process, which dramatically reduces both the temperature and time required for graphitization, won a prestigious 2025 R&D 100 Award.

Details

- The “Electrochemical Graphitization in Molten Salts (E-GRIMS): A Game Changer for Sustainable Graphite Production” was developed through CMI project led by Sheng Dai at Oak Ridge National Laboratory.

- CMI researchers developed a lower-temperature and non-catalytic process that significantly reduces energy use compared to conventional methods for converting amorphous carbons from versatile precursors such as biomass and coal into graphite for energy storage and conversion.

- They developed a new method of graphitization to enable faster graphitization at much lower temperature (850 °C) compared to the conventional process (>3000°C).

- Understanding the mechanism of electrochemical graphitization in molten salts is critical.

Hub Targets Addressed

- Process intensification to improve material and manufacturing efficiency

- Efficient use of energy and water