CMI researchers from Ames National Laboratory conducted the activity for this highlight

Innovation

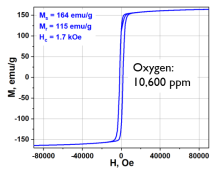

Washing optimization significantly improves magnetic properties of Nd2Fe14B permanent magnet powders obtained via a one-step calciothermic reduction.

Achievement

Produced Nd2Fe14B powders with nearly ideal magnetization (99% theoretical) by post-processing the heat-treated samples before washing.

Significance and Impact

One-step calciothermic procedure circumvents the energy-intensive neodymium metallization process with direct production of Nd2Fe14B permanent magnets from Nd2O3 and Fe/FeB, Our innovation brings a significant improvement to the post-processing, bringing us one step closer to successful magnet demonstration.

Hub Target Addressed

Energy-efficient rare earth metals production.