CMI researchers at Idaho National Laboratory, OLI Systems and University of Arizona lead the activity for this highlight with researchers at Rutgers University and Purdue University

Innovation

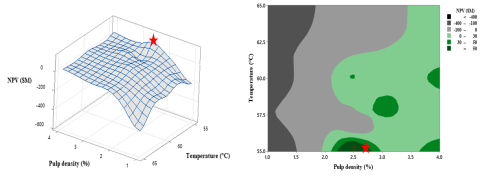

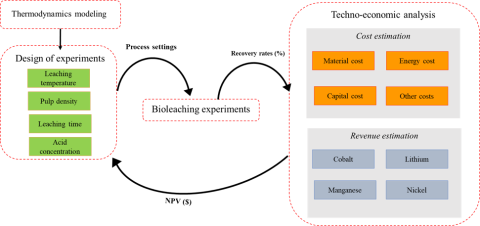

Optimization of lithium-ion battery (LIB) bioleaching was guided by design of experiments using iterative response surface methodology and thermodynamic modeling.

Achievement

- Best bioleaching condition was determined to be 55°C for 30 h with 2.5% LIB using corn stover-based biolixiviant containing 75 mM gluconic acid.

- Metal solubilization was 100% for Li & Mn, 86% for Co, 84% for Ni.

- Thermodynamic predictions for Co recovery were consistent with observations.

Significance and Impact

Technology development accelerated by targeting NPV (rather than efficiency of metal recovery) and using thermodynamic insight.

Hub Target Addressed

Advancing environmentally friendly and efficient recovery of critical materials from end‐of‐life products or wastes.