CMI researchers from Colorado School of Mines conducted the activity for this highlight

Innovation

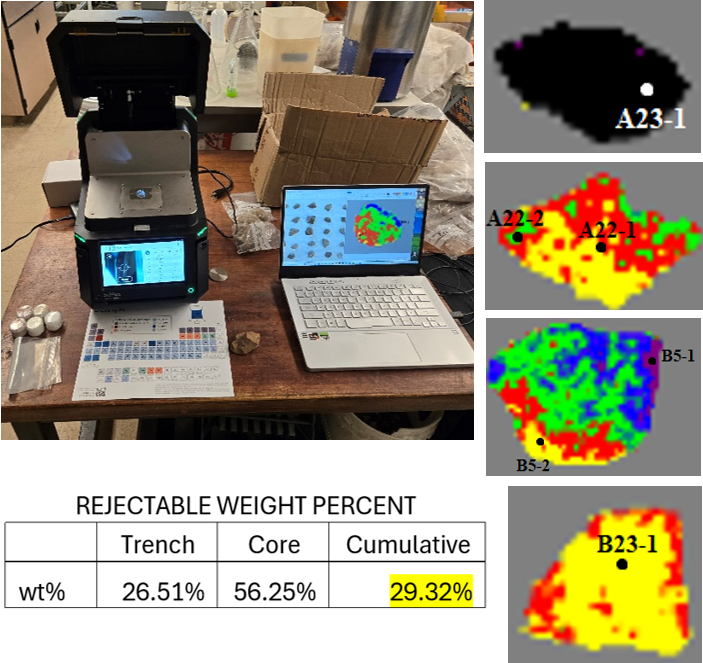

Implementation of new x-ray fluorescence (XRF) technology to verify ore sortability.

Achievement

SciAps’ state-of-the-art 80kV Powerhouse XRF enabled point analysis of specimens scanned for sortation. Results indicate that XRT sortation is ~90% accurate & may enable rejection of 25% ±5% of the deposit’s weight before crushing.

Significance and Impact

- XRT sortation technology seems to be effective at classifying rare earth ore.

- Savings in water & energy usage are directly proportional to the deposit’s “rejectable” weight percent.

Hub Target Addressed

Developing processes to recover and separate REEs from traditional or unconventional sources.