CMI researchers at Oak Ridge National Laboratory and Purdue University conducted the research for this highlight

Innovation

CMI-supported collaboration advanced Technology Readiness Level (TRL) of Big-Area Additive Manufacturing (BAAM) for magnet production using Techno-Economic Assessment (TEA), Life Cycle Assessment (LCA).

Achievement

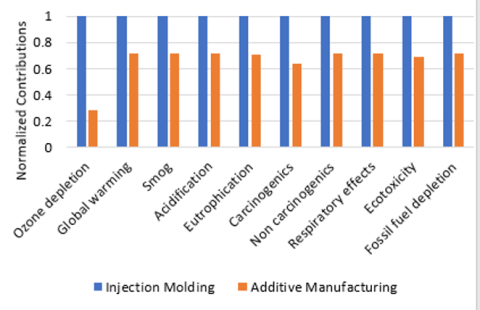

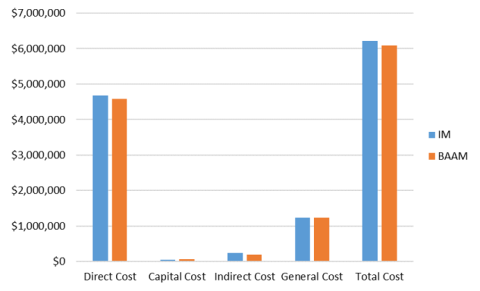

- Analyzed the economic and environmental feasibilities of a newly developed BAAM technology for producing NdFeB magnets relative to a traditional method: injection molding (IM).

- Predicted that BAAM can increase the profit by 9.07% and lower the global warming potential by up to 30%.

Significance and Impact

TEA and LCA results for BAAM magnet production are economically and environmentally superior to IM. Plan to explore technology at higher TRL.

Hub Target Addressed

Provide decision-making insight to research and development; accelerate advanced material development and deployment.