CMI researchers from Oak Ridge National Laboratory and Ames National Laboratory conducted the activity for this highlight

Innovation

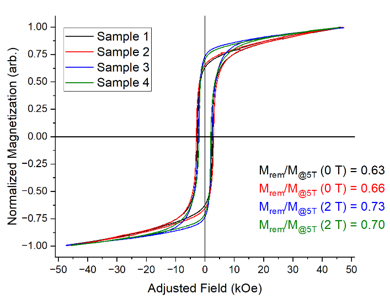

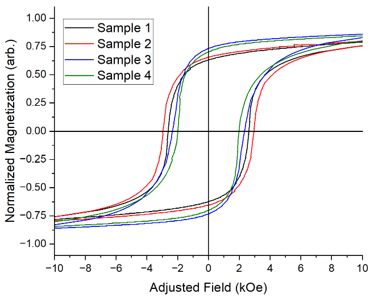

Hydrogenation-Disproportionation-Desorption-Recombination (HDDR) processed powders were produced in an applied field of 2 T and resulted in increased magnetic anisotropy.

Achievement

Accepted manuscript in Metals journal. Described reproducible HDDR process results demonstrating improved magnetic anisotropy.

Significance and Impact

- Established a new process to produce anisotropic HDDR powders

- Bonded Nd-Fe-B is the primary type of Nd-Fe-B magnet produced in North America; hence, production of enhanced powders can enable the U.S. magnet industry.

Hub Target Addressed

- Bringing a competitive advantage to domestic suppliers of bonded magnets.

- Improving material performance resulting in the use of smaller volumes of critical rare earths via lower loading fraction in bonded magnets and supplanting sintered magnets with bonded magnets.