CMI researchers from Ames National Laboratory and Terves conducted the activity for this highlight

Innovation

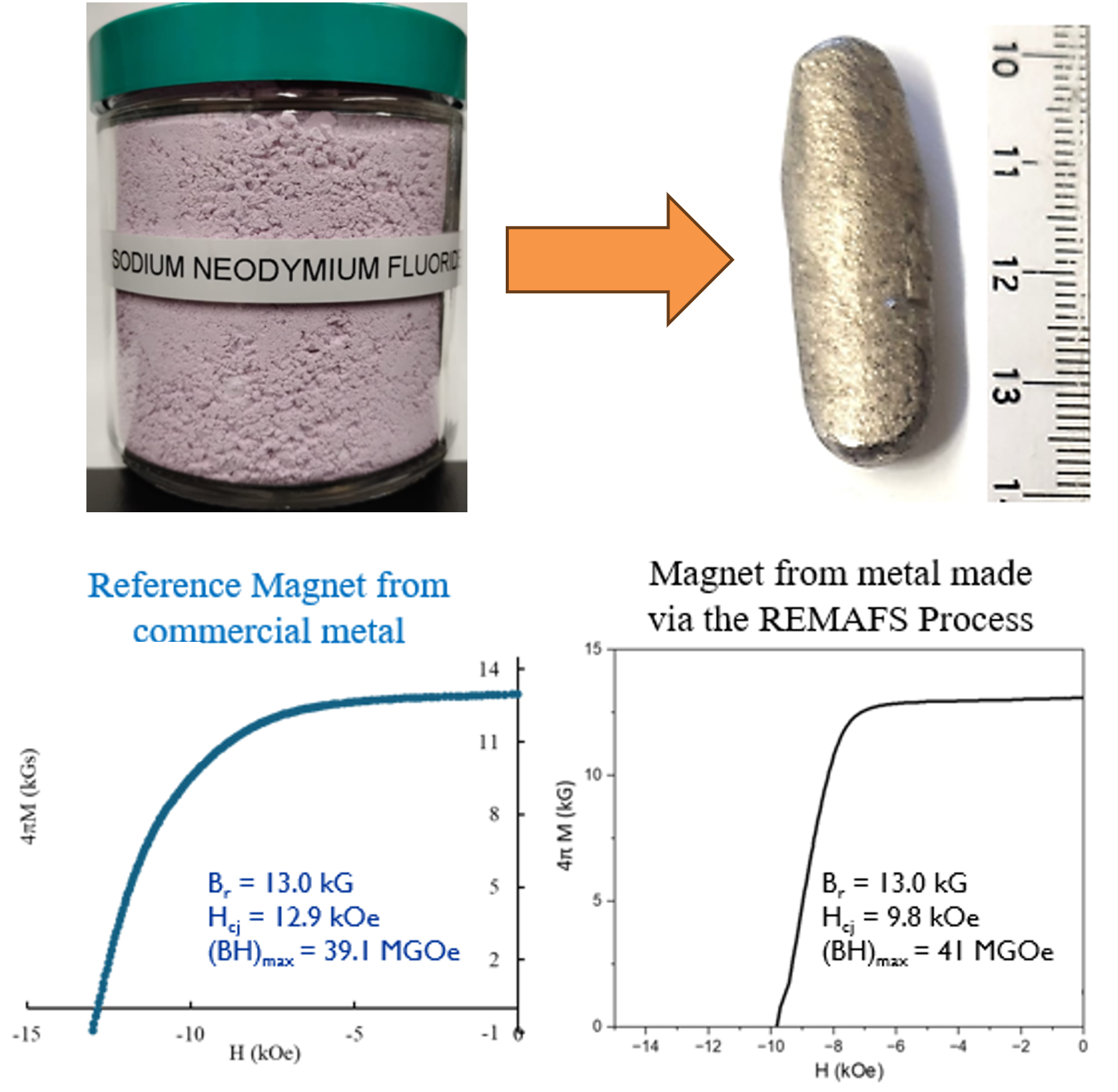

CMI researchers have demonstrated a 41 MGOe Nd-Fe-B magnet fabrication using the REMAFS (Rare Earth Metals via Alternative Fluoride Salt) process.

Achievement

The REMAFS process is based on the metallothermic reduction of Na-RE-F or similar salts, produced without the use or generation of HF. The REMAFS is of an equivalent magnet grade (N40) compared with a magnet of similar elemental constitution made with commercial REE metal.

Significance and Impact

- First Nd-Fe-B magnet production based on the new feedstock bypassing use or generation of hazardous HF.

- Support domestic Nd metal and Nd-Fe-B magnet production.

- Exceeds the focus area goal of a 40 MGOe magnet.

Hub Target Addressed

Energy-efficient rare earth metals and magnet production.