News & Highlights

Azo Materials: New technology for processing rare earth metals licensed to Principal Mineral

Research Highlight

Research Highlight

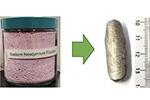

Rare earth metal production scaling using REMAFS

Research Highlight

Research Highlight

Successfully produce dysprosium metal using REMAFS process

CMI rare earth metal production technology licensed

In the News

In the News

Researchers develop a new, non-toxic method for rare earth metal processing

The main goals of this project are develop kg-level production at ambient conditions of anhydrous rare earth fluoride from the recycled rare earth-containing waste streams without any hydrofluoric acid or ammonium bifluoride use; demonstrate commercial-grade rare earth metal production; and energy-efficient rare earth metal production technology from the recycled materials through the synergetic adjustment of recovery and reduction steps (the target is 50-80% reduction of carbon intensity). The outcome of this project will be a successful demonstration of commercial-grade rare earth metal production (kg-scale batches), supported by Techno-Economic Analysis (TEA) and Life Cycle Assessment (LCA).