News & Highlights

Research Highlight

Research Highlight

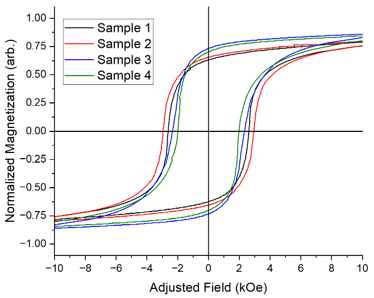

Applied magnetic field increases magnetic anisotropy in HDDR-processed Nd-Fe-B alloy

Hydrogen-disproportionation-desorption-recombination under applied magnetic field

Research Highlight

Research Highlight

CMI-trained researcher supports U.S. magnet industry at MP Materials

Research Highlight

Research Highlight

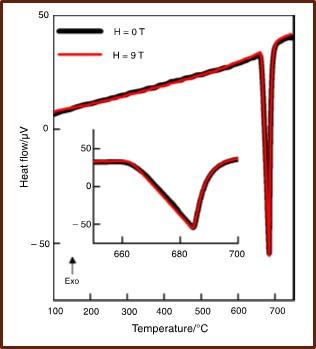

A rapid heating and high magnetic field thermal analysis technique

Research Highlight

Research Highlight

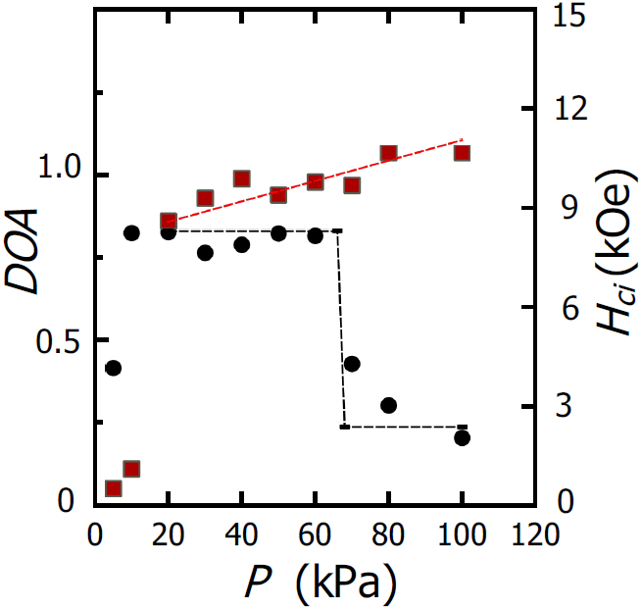

Critical hydrogen pressure for HDDR-formed NdFeB powder

Michael Kesler at Oak Ridge National Laboratory leads the CMI project "Enhancing Hydrogenation-disproportionation-desorption-recombination (HDDR) powders"

This project attempts to develop high performance magnet powders for use in different applications, including bonded magnets, with a focus on understanding of thermomagnetic processing for achieving superior magnetic properties over standard processing routes. While application of high fields can affect reaction rates and pathways by altering thermodynamic barriers or interfacial free energies (e.g., the Zeeman Effect, which effectively increases reactivity of the processing gases), little systematic work has been done on permanent magnets. Compounds with high magnetocrystalline anisotropy are ideal candidates to explore mechanism by which large magnetic fields can enhance grain alignment, chemical ordering, and phase selection to improve remanence and saturation magnetization.