News & Highlights

Research Highlight

Research Highlight

Improved critical materials recovery from LIB black mass by MSX

In the News

In the News

ORNL: Process to recover metals from batteries licensed by Momentum Technologies

Momentum licenses MSX technology for lithium ion battery (LIB) materials recovery

Research Highlight

Research Highlight

Separation and recovery of cobalt from spent lithium ion batteries (LIBs) with supported Membrane Solvent Extraction (MSX)

In the News

In the News

STEM Magazine From Trash to Treasure: Electronic waste is mined for rare earth elements

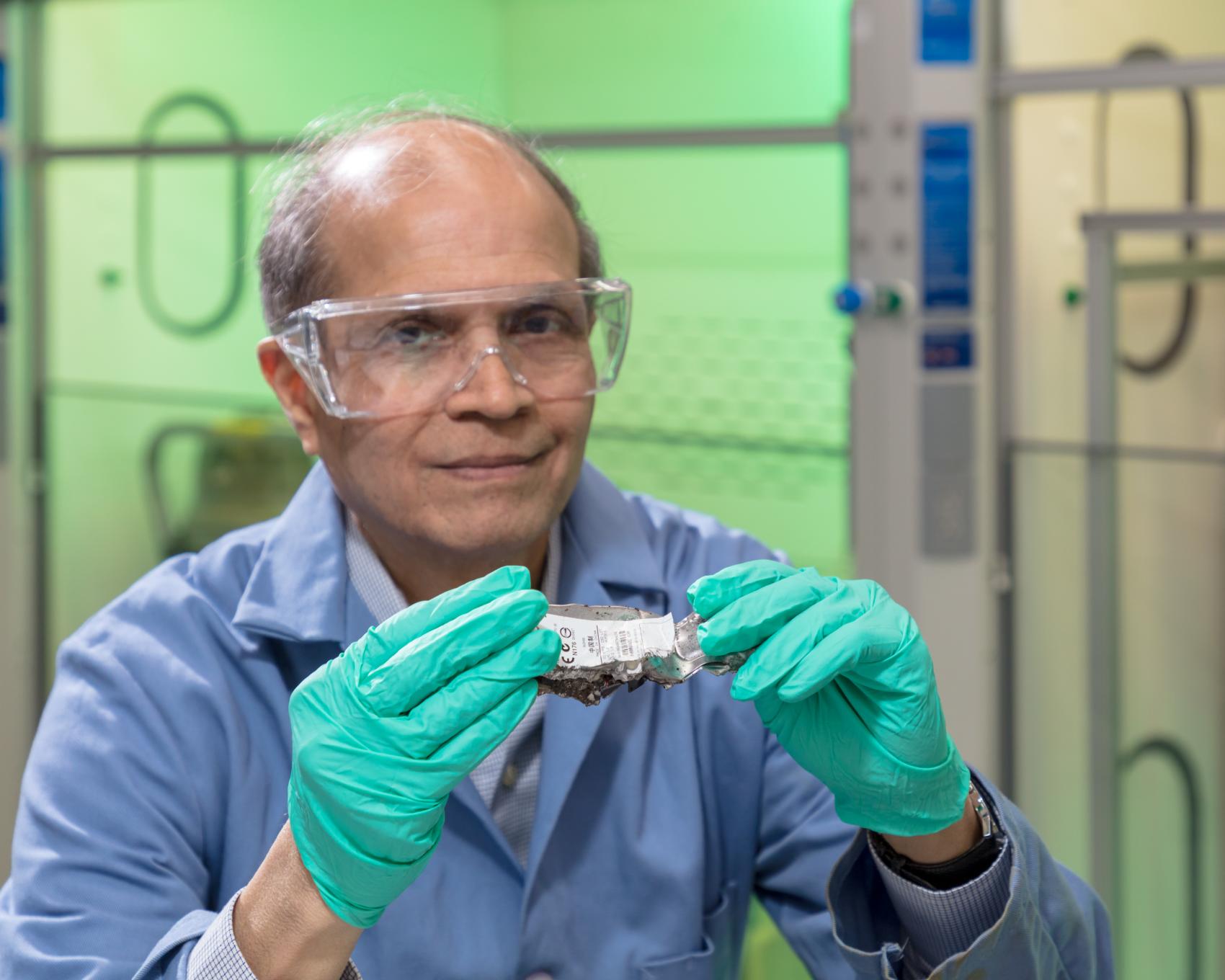

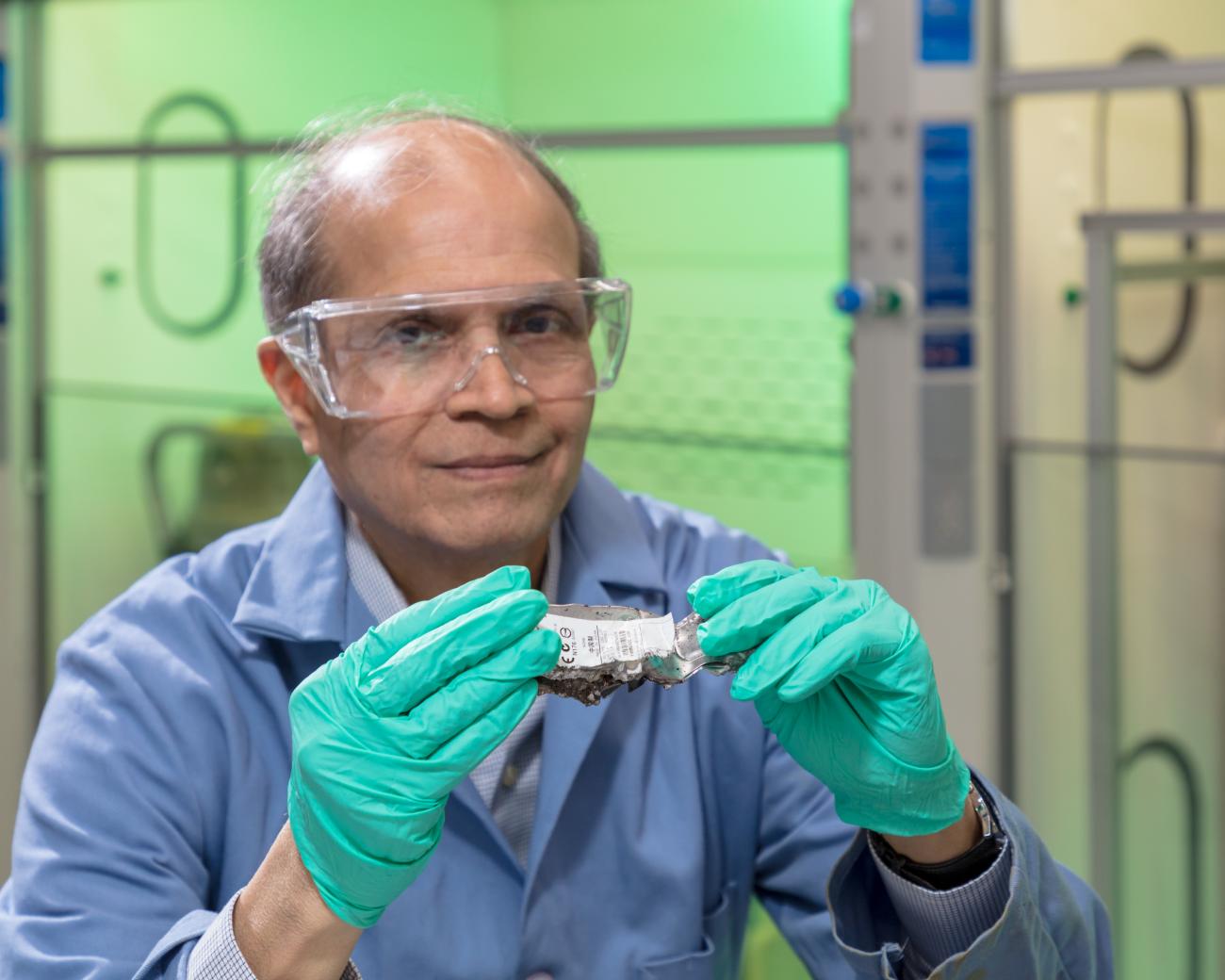

Ramesh Bhave at Oak Ridge National Laboratory leads the CMI project "Separation and recovery of cobalt from e-waste"

In this project, the recovery and separation of cobalt from e-wastes, including scrap and spent lithium ion batteries (LIBs), will be conducted using a novel energy efficient, cost-effective and environmentally friendly supported membrane solvent extraction (MSX) process. After developing the separation methods, liquid membrane composition and the process parameters will be comprehensively investigated and optimized to achieve high purity (>99%), recovery (>95%), and extraction rates for cobalt recovery. The versatility of the MSX process will be demonstrated for separation and recovery of cobalt from wide variety of feedstocks such as swarf and scrap LIBs. Furthermore, the long-term stability studies of extractants used in MSX processes will also be carried out.

Related information:

CMI Webinars - several CMI webinars have been offered related to recycling and to this project

Earlier work related to this project led to the first CMI license