News & Highlights

Research Highlight

Research Highlight

CMI works with industry to provide specialty training for new hire

Research Highlight

Research Highlight

CMI technology Tough SmCo magnet wins R&D100 Award

Two CMI technologies named 2021 R&D 100 Award winners

News Release

News Release

Tough magnet tech scores an R&D100 award for Critical Materials Institute at Ames Laboratory

Research Highlight

Research Highlight

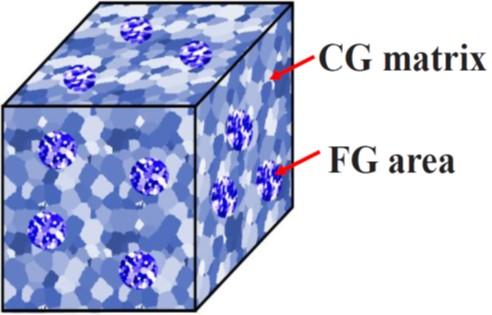

Heterogeneous grain engineering overcomes mechanical fragility in Sm-Co magnets A

Project Team

Principal Researchers

Baozhi Cui at Ames Laboratory leads the CMI project "Heterogeneous samarium-cobalt (SmCo) & neodymium-iron-boron (NdFeB) magnets"

Rare-earth permanent magnets (REPMs) have excellent magnetic properties and have been widely used in energy conversion and storage, telecommunication, consumer electronics, and sensors. However, REPMs are quite brittle and impossible for applications with high stress and vibration. The brittleness also leads to the magnet production loss up to 30 percent. This project produces REPMs (mainly SmCo and NdFeB sintered magnets) mechanically and magnetically stronger than the commercial products, while reducing REPM waste rate to less than 10 percent. The novel magnets will be more powerful, more efficient, and less-weight for energy-related applications while reducing the pressure on critical material supply chain.

Research technology developed in this project won a 2021 R&D 100 Award LINK

Research technology developed in this project was further explored by Baozhi Cui at Ames Laboratory and CMI Team member Energy Electron Corporation and is described in these news stories:

Ames Laboratory produced this video about "Tough SmCo," which was developed at Ames Laboratory with industry partner Energy Electron Corporation and won a 2021 R&D 100 Award.