News & Highlights

Research Highlight

Research Highlight

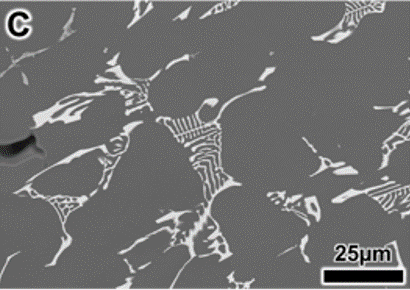

Direct reduction of cerium oxide by liquid aluminum a mechanistic understanding for industrial adaptation

Research Highlight

Research Highlight

CMI-trained researcher moves from AI to neutrons

In the News

In the News

Mini hydro company raises $18M to generate power in canals

Research Highlight

Research Highlight

Direct reduction of cerium oxide advances Al-Ce alloying

Research Highlight

Research Highlight

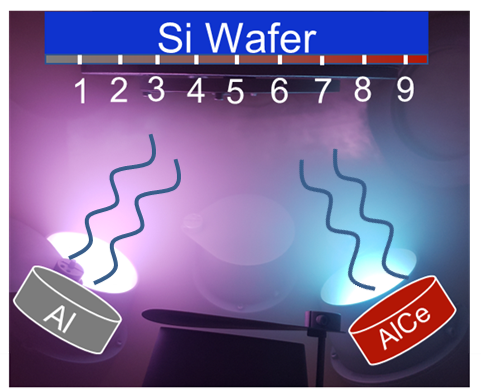

Coefficient of thermal expansion (CTE) determination of Al-Ce alloys via combinatorial thin-film synthesis

Publications

Ternary interactions and implications for third element alloying potency in Al–Ce-based alloys

The efficacy of replacing metallic cerium in aluminum–cerium alloys with LREE mischmetal

Developments in aluminum-scandium-ceramic and aluminum-scandium-cerium alloys

Improved high-temperature aluminum alloys containing cerium

Orlando Rios at University of Tennessee Knoxville (UTK) leads the CMI project "Science-Enabling Diverse Value Chain Product from Aluminum-Cerium Alloys"

This work targets specific science problems to enable diverse value chain development for aluminum-cerium alloys, identifying interfacial structure and reaction thermodynamics for better strength at elevated temperature, higher ductility, and lower cost. The project investigates the use of rare earth element precursor compounds as feedstock for direct reduction alloying. This technology can be used for large volume casting technologies like die casting and high-performance applications such as turbochargers, pistons, and cylinder heads. If successfully developed, this technology will streamline processing of lanthanide precursor compounds improving economic competitiveness and providing a domestic demand stream through aluminum alloying.

Related information:

Leadership Development: Scott McCall

R&D 100 Award

TechConnect Innovation Award