After being stabilized in an ambulance as he struggled to breathe, Jonathan Harter hit a low point. It was 2020, he was very sick with COVID-19, and his job as a lab technician at Oak Ridge National Laboratory was ending along with his research funding.

“It was a weird situation where I felt a little bit powerless — again. I thought, ‘If I don’t create an opportunity for myself, I’m done,’” he said.

Harter had been in challenging spots before. A first-generation college student from the local Tennessee hamlet of Walland, Harter was selected for an ORNL robotics internship in 2016 that helped pay his way through nearby Pellissippi State Community College. When the internship ended, he had to convince his ORNL supervisor to fund him for the first time through another internship.

It worked, and Harter has continued tackling tough challenges at ORNL ever since. His initiative and perseverance have frequently enabled him to turn dead ends into possibilities. Today he is a technical professional in the Energy Science and Technology Directorate, specializing in electronics recycling and high-voltage technologies.

“I knew I could learn quickly. I just needed a few people to believe in me and trust me to do important things,” said Harter. “If you throw me into the fire, I figure it out.”

The first to hand Harter a big assignment was now-retired ORNL senior researcher Tim McIntyre, who was developing automation processes and controls for recovering critical materials from hard drives and electric vehicle, or EV, batteries. Harter credits McIntyre with providing him opportunities as an intern for meaningful responsibility and research, including developing projects and inventing disassembly methods and processes.

After Harter became a lab technician, McIntyre helped him improve his technical communication skills by sharing presentation and reporting duties. McIntyre encouraged Harter to act as a liaison with recycling companies to learn more about their needs, the technology they might adopt and details of their business operations. In many cases, companies indicated they were shredding entire batteries or hard drives for disposal without separating components for reuse.

Automated disassembly is safer and improves the quality and value of extracted materials such as copper and aluminum. “We like to talk about recovering the value instead of recycling,” said Harter, who earned two patents in the process.

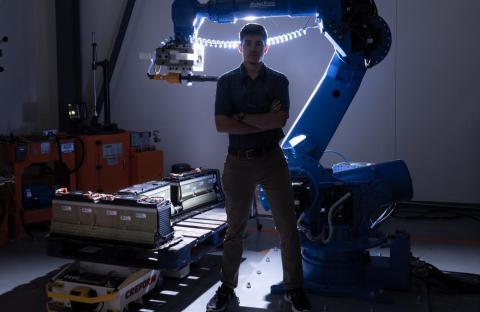

McIntyre and Harter demonstrated the fast, efficient recovery of rare earth magnets from hard drives for direct reuse, which is the goal for both profitability and environmental benefit. They also developed automated processes to recover materials and components from EV drivetrains and automotive lithium-ion batteries. The heart of the process is a large six-axis industrial robot arm with custom tooling. The duo chose an older, off-the-shelf robot to show that the process could be affordable for scrap shops, enabling more widespread adoption of advanced recycling. The robot’s pivoting, bright blue arm, with an “elbow” that bends above Harter’s head, is guided by a controller and machine vision as it unscrews the bolts on an energized EV battery assembly.

For Harter, who takes all the safety training he can, working with the automated robot was appealing partly because its use could protect workers in salvage yards and maintenance shops from handling dangerous voltages.

Link to the full story: Recycling revival: Jonathan Harter’s initiative brings creative problem-solving to EV battery recycling