Windus named ACS Fellow

Theresa Windus, the Interim Director of Chemical and Biological Sciences at Ames Laboratory and Distinguished Professor of Chemistry and Liberal Arts and Sciences Dean’s Professor at Iowa State University, has been named a Fellow of the American Chemical Society (ACS).

Theresa Windus, the Interim Director of Chemical and Biological Sciences at Ames Laboratory and Distinguished Professor of Chemistry and Liberal Arts and Sciences Dean’s Professor at Iowa State University, has been named a Fellow of the American Chemical Society (ACS).

The ACS Fellows Program recognizes members for their outstanding achievements in and contributions to the science of chemistry, and for their service to ACS.

Windus, one of 53 members named to the 2020 class of Fellows, will be honored at the ACS Fall National Meeting, to be held virtually in August. READ MORE

All-hands panel discussion covers COVID concerns

Ames Laboratory will be hosting an All Hands COVID Resources Panel Discussion on Aug. 12 to

highlight resources the University and Laboratory offer in response to the pandemic. The discussion will consist of subject matter experts from the following areas of expertise.

- WellBeing

- Employee and Family Assistance Program

- Childcare/Return to Learn

- Employee Leave and Alternative Work Agreements

- Disability Accommodations

- Laboratory Planning and Recovery

- Laboratory Communications

Panelists will discuss their area of expertise, the resources that are available to employees, and where to find the information. The discussion will also be recorded for later viewing.

Virtual Log-in Information:

Date: Wednesday, Aug 12, 2020

Time: 10:00 am | 1 hour | (UTC-05:00) Central Time (US & Canada)

Meeting number: 120 586 5457

Password: work-safely

https://iastate.webex.com/iastate/j.php?MTID=m479c53f9e054b0af17058ab27353d8cf

Join by video system

Dial 1205865457@iastate.webex.com

You can also dial 173.243.2.68 and enter your meeting number.

Join by phone

+1-312-535-8110 United States Toll (Chicago)

Access code: 120 586 5457

Ames Lab-led team wins $12.8M from DOE to tackle plastic upcycling science

Plastic waste is everywhere in the United States, rapidly piling up in our landfills, leaching into and clogging our waterways. Yet the nearly 27 million tons generated in the US in 2017 (EPA) is full of energy and carbon value, which is currently lost.

The global accumulation of plastic waste creates energy, environmental, and human health concerns. Now a multi-institutional team of scientists led by the U.S. Department of Energy’s Ames Laboratory, which has been working on the problem for almost three years, is growing into the Institute for Cooperative Upcycling of Plastics (iCOUP) Energy Frontier Research Center (EFRC), with $12.8 million in funding over four years. Announced July 1 by Energy Secretary Dan Brouillette, the DOE’s EFRC program is designed to bring together multi-disciplinary teams of scientists to take on some of the defining energy challenges of the 21st Century— in this case, plastic waste upcycling.

“We’re very excited to have the support of the DOE to pursue the discovery of new concepts that will enable plastic upcycling. The multi-disciplinary collaborations that are part of an EFRC are key to addressing fundamental scientific challenges in plastic upcycling,” said Aaron Sadow, Director of iCOUP. Sadow is a scientist in the Division of Chemical and Biological Sciences at Ames Laboratory, as well as a professor of Chemistry at Iowa State University. READ MORE

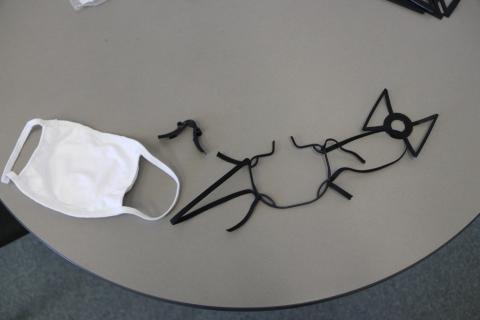

Improving the fit of face coverings

By now, we’ve all become accustomed to wearing a face covering as a first line of defense against COVID-19. And we also know the frustration of having one that doesn’t fit quite right – whether it’s homemade, a non-medical surgical mask or an N-95 version.

To get a handle on the fit issue and help address those problems, Ames Laboratory’s Environment, Safety and Health director Sean Whalen and scientist Julie Slaughter conducted a survey of Ames Lab employees. The online survey, emailed in June, drew responses from 93 people.

“Most people who responded (47.25%) typically use homemade cloth face coverings, followed by non-medical surgical masks (25.27%), and employer-provided masks,” Slaughter said. “Ear loops (78.02%) were the most common attachment method.”

The main two survey questions dealt with fit and comfort. On fit, gaps around the nose was the top issue with gaps around the top and sides and being too small were close behind. On comfort, fogging glasses was the top complaint followed by “too hot” and touches the mouth.

Armed with that information, Slaughter set to work designing a plastic, 3D-printed frame that would help with the fit around the nose while holding the fabric covering away from the mouth. She worked with ISU's ME and IMSE departments on design iterations, received prototypes from other national labs and hired an AeroE student, Justin Lajoie, “with lots of 3D printing experience” to help with the design. Justin has been instrumental in the rapid development of these frames.

“We’ve gone through more than 10 design iterations and are still making some small changes,” Slaughter said. “It is very easy with our new 3D printer to modify the design and test the changes - typically about 1 hour to print a new design.”

The near-final frame design has a few sizes that work with Ames-provided, ISU-provided, and other cloth face coverings. The white lab-provided coverings and the ISU-provided coverings were tough to fit because they don't have much excess fabric. Homemade face coverings (pleated or not) work easier with the design because they tend to have more fabric.

While 3D printing is fine for the design phase, actual production of the frame will be handed off to a commercial firm. Slaughter said ISU’s Center for Industrial Research and Service (CIRAS) is helping identify companies that do injection molding.

Work on the project is supported by the DOE Office of Science through the National Virtual Biotechnology Laboratory, a consortium of DOE national laboratories focused on response to COVID-19, with funding provided by the Coronavirus CARES Act.

IT to offer limited on-site support

Starting July 30th, IT will have limited staff onsite in 334 TASF on the following days between 9:00 AM and 1 :00 PM:

Tuesday - Kurt Hulsebus Thursday - Mark Clarridge

If you need to visit IT staff while they are on site, please create an IT Request ticket in ServiceNow to schedule a time (https://now.ameslab.gov/sp).

New employees join the Lab

Even though they haven't spent much time physically at the Lab, several new employees have joined the Lab recently. Please welcome Laura Graves, Brandon Kester, Nancy Turner and Tyler Slade.

Laura Graves is the new Administrative Specialist who will be working with Director Adam Schwartz to help handle many of his day to day operations. She will be assisting with various budgets, the director’s office daily tasks, and supporting the exec team.

Laura Graves is the new Administrative Specialist who will be working with Director Adam Schwartz to help handle many of his day to day operations. She will be assisting with various budgets, the director’s office daily tasks, and supporting the exec team.

Graves comes to the Lab from ISU's Kinesiology department where she was an academic adivsor and was with ISU's Accounts Receivable Office prior to that. She was born and raised in the West Des Moines area and attended the University of Northern Iowa. While at UNI, she played on the school’s softball team all four years and majored in Family Services. After graduating, she went to the University of Kansas and obtained a Master’s in Higher Education Administration.

Graves lives in Nevada with her husband of six years, Nathan. They have two little girls, Scottie who is three and Isabelle who is three months. Besides the girls keeping them on their toes, they have regularly attended a CrossFit gym in Nevada for six years and continue to find new ways to stay active.

Brandon Kester is a Program Assistant II in Property Services, reporting to Stephanie Goodman. In his position, he will assist in all aspects of the Property operation, providing administrative control for government-owned Personal Property (capitalized, sensitive, high risk, and accountable

Brandon Kester is a Program Assistant II in Property Services, reporting to Stephanie Goodman. In his position, he will assist in all aspects of the Property operation, providing administrative control for government-owned Personal Property (capitalized, sensitive, high risk, and accountable

U.S. Government Personal Property, including Precious Metals).

Kester comes to Ames Laboratory from VB Seals, Inc. where he served as warehouse shipping manager and international shipping manager. He has an associate of science degree in Business Administration from DMACC.

Kester lived in Boone throughout his elementary years before relocating to Gilbert for middle school and high school. He lives in Ames with his wife Jackie, who is an adviser in Aerospace Engineering. They plan to have kids eventually, but recently adopted a small, three-year-old "pupper" and have another small pup joining the family in September.

In their spare time, "we’re pretty big board game nerds (modern euro games, not monopoly-type games). I’m also into reading/collecting graphic novels, running marathons (when I can stay in shape), and hanging out with friends and family to barbeque and/or bonfire. Other than that, we try and travel to Europe every summer with my in-laws for a few weeks (although Covid-19 has taken care of that for the moment."

Nancy Turner is Project Coordinator. helping facilitate projects and administrative tasks for Andrea Spiker and Steve Hamilton. So far, she has been involved with the Lab Plan, ALORC, Space, Strategic Plan Implementation Plan, and the PEMP.

Nancy Turner is Project Coordinator. helping facilitate projects and administrative tasks for Andrea Spiker and Steve Hamilton. So far, she has been involved with the Lab Plan, ALORC, Space, Strategic Plan Implementation Plan, and the PEMP.

Prior to coming in the Lab, Turner held several positions at Wiley, most recently as a managing editor. During that time she attended ISU and received my MA in Rhetoric, Composition and Professional Communication. She has a bachelor's degree in English and Writing from Drury University in Springfield.

A native of Norwalk, she has a little boy, Jackson, who's about to turn six and will begin Kindergarten this fall. Her favorite things are being a mom, gardening, baking, reading, writing, and drinking coffee. She says they love spending time with her family, bikes ride and building Legos.

Tyler Slade is a postdoctoral research associate with Ames Lab physicist Paul Canfield. He is involved in the crystal growth and physical property characterization of magnetic semimetals with topologically non-trivial electronic structures.

Tyler Slade is a postdoctoral research associate with Ames Lab physicist Paul Canfield. He is involved in the crystal growth and physical property characterization of magnetic semimetals with topologically non-trivial electronic structures.

He grew up in Phillips Wisconsin, which is a very small town in the rural northern part of the state. He attended the University of Wisconsin-Madison for his undergraduate degree and completed by graduate work at Northwestern University where he studied thermoelectrics with Prof. Mercouri Kanatzidis.

He lives near downtown Ames with his fiancée Erin Young, who teaches fifth grade at Fellows Elementary School. They will be getting married in early August. In his free time he enjoys reading and playing guitar, as well as outdoor activities including downhill skiing, fishing, and camping.

Procedure for "attending" virtual conferences

With virtual conferences becoming increasingly more common among Ames Laboratory employees it's important to know what the process is for registering and paying for a virtual conference. Since the conference is virtual there should be no travel involved. This means no Conference Management approval is needed and no Travel Worksheet is required.

The only thing a virtual conference attendee needs to do in order to pay for their registration is complete is a purchase requisition and submit it to Procurement via our Smartsheet tool at: (https://app.smartsheet.com/b/

Along with their requisition submission, the attendee will need to provide the registration link. Requests should be submitted in a timely manner, if possible.

A Purchasing Agent will reach out to the requester within a day or two to process the registration. If the virtual conference registration must be completed in less than 5 working days please contact Procurement for guidance: purchasing@ameslab.

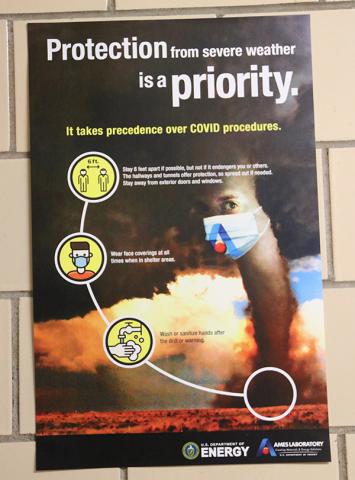

NOTE: The Severe Weather Drill scheduled for Thursday Aug. 6, has been postponed until Thursday, Aug. 20 at 10 a.m.

Severe weather drill Aug. 6

While spring has come and gone, Iowa can experience severe storms any time of the year.

While spring has come and gone, Iowa can experience severe storms any time of the year.

Severe weather warnings may trigger sheltering requirements. In the event of a warning, staff are required to follow sheltering instructions. The immediate severe weather threat takes priority over potential COVID exposure.

During the drill, or if an actual event occurs, please attempt to maintain physical distancing when sheltering. Staff may spread out into the tunnels between Spedding, Wilhelm, and Metals Development if needed. Face coverings are required in shelter areas.

Additional COVID safety signage is posted in shelter areas. Please contact Sean Whalen with any questions: sbwhale@ameslab.gov or 515-294-4965.

Remember safety when returning to work

As we ramp up activities at the Lab in our current COVID pandemic environment, we want to remind you to take the time and consideration necessary for all aspects of safety. There has been a surge in serious incidents at National Laboratories, raising concerns at DOE headquarters.

On July 28, Juston Fontaine, Deputy Director for Field Operations (DDFO) for the Office of Science, expressed the following concern:

Within the course of one hour this afternoon, I received three separate safety incidents from three separate laboratories which I consider serious. As we began to increase operations at our labs over the course of the last several weeks, we collectively discussed the need to enhance our due diligence and institute a back to basics approach regarding safety operations and oversight.

Collectively, these events are concerning. I ask that each of you please take a moment to reiterate the need to rethink basic safety considerations with each of your lab counterparts as we execute work in the midst of varied operational states in the current COVID environment.

I have been extremely pleased with the ability of our complex to execute mission critical activities in this environment. However, if we cannot ensure the safety of our workforce in executing these activities in a curtailed environment, it may become necessary to reconsider work being currently being conducted and possibly halt specific operations.

We are asking our Operations and Research leads to share this information with your staff, and encourage everyone to Stop, Think, Check, and Do Work Safely. Perform the following tasks before beginning work or opening up your space: take time to walk the space and look for hazards; think about what may have changed since work was last conducted in the area; check chemicals, equipment, and safety items; and ensure that staff working in the area have reviewed SOPs, readiness reviews, and are mentally prepared to have a safe day.

Thanks – Steve and Jamie

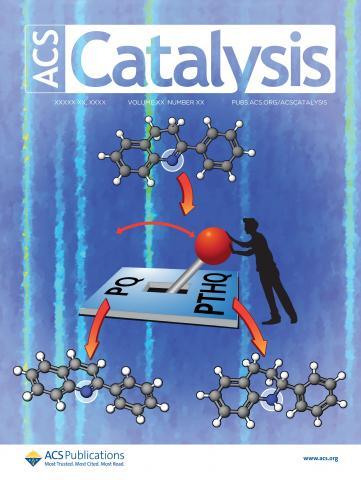

Shedding light on complex chemical reaction networks

Scientists at Ames Laboratory and their colleagues have discovered a way to untangle the mysteries of complex reaction networks by employing a measurement tool in a unique way.

Scientists at Ames Laboratory and their colleagues have discovered a way to untangle the mysteries of complex reaction networks by employing a measurement tool in a unique way.

Catalysis is a fundamental chemical process used in many manufacturing industries-- it speeds the breakdown or combination of compounds into new ones, for the production of things as varied as foods, medicines, plastics, and fuels. Making catalysis more precise, efficient and multi-functional has the potential to reduce the number of steps in manufacturing processes, reduce waste or harmful byproducts, and reduce energy consumption.

To do this, Ames Laboratory associate scientist Long Qi used a newly-developed tool, called operando magic angle spinning nuclear magnetic resonance spectroscopy (operando MAS-NMR), and applied it to catalytic reactions at real time under high pressure. In this way, Qi was able to map the complex activity unfolding as a catalyst transforms and rearranges molecules. READ MORE

Accelerating commercialization of CMI technologies

Ames Laboratory is using its public-private partnership strategy to tackle a perennial R&D challenge— the often long and twisting road to deploying a technology commercially.

Ames Laboratory is using its public-private partnership strategy to tackle a perennial R&D challenge— the often long and twisting road to deploying a technology commercially.

Ames Laboratory is partnering with Decision Frameworks, a Houston-based company specializing in Decision Quality enablement, to enhance navigation of the commercialization process for the Critical Materials Institute (CMI), a U.S. Department of Energy Innovation Hub overseen by Ames Laboratory.

CMI’s mission is to address supply chain shortages in rare-earth and other materials critical to domestic manufacturing. Since its inception in 2013, the CMI team of national laboratories, universities, and industry partners have racked up an impressive list of achievements, including 17 patents, 10 licensed technologies, and four R&D100 awards. READ MORE

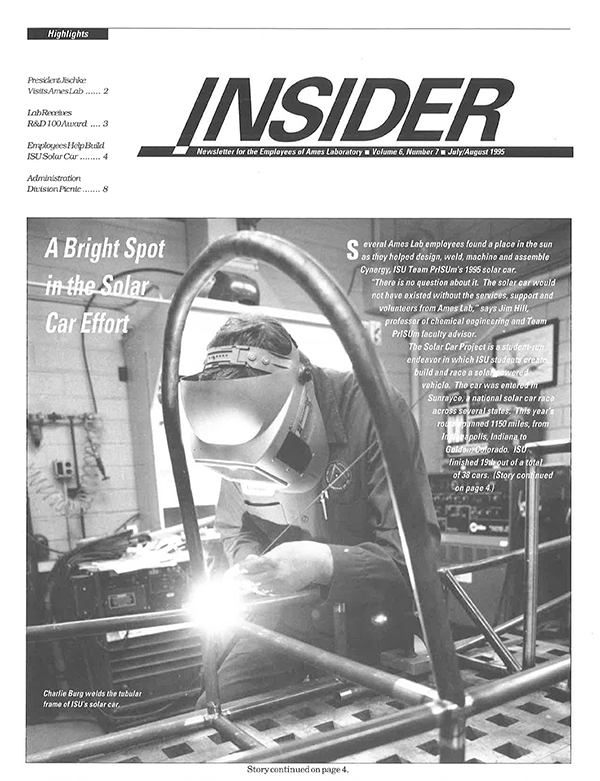

Looking Back: Insider highlights assistance to ISU solar car team

The July 1995 issue of Insider had a cover story on the technical assistance Ames Lab provided to the ISU solar car team. Ames Lab machinists, engineers, electronic technicians and administrators provided design skills, technical advice, shop time and enthusiastic support to help create a TeamPrISUm solar car. Hundreds of hours were spent planning, designing, welding and assembling this unique vehicle for the July race.

The July 1995 issue of Insider had a cover story on the technical assistance Ames Lab provided to the ISU solar car team. Ames Lab machinists, engineers, electronic technicians and administrators provided design skills, technical advice, shop time and enthusiastic support to help create a TeamPrISUm solar car. Hundreds of hours were spent planning, designing, welding and assembling this unique vehicle for the July race.

Elsewhere in the issue, a visit by ISU President Martin Jischke was documented with lots of photos, the admin division held a hot picnic, and personal profiles shared Kay Hannasch's travel bug and Marek Pruski's pursuit of big fish.

To read the entire issue, click on the cover.