News & Highlights

Research Highlight

Research Highlight

Dimensionally stable anode for sustainable Nd metal production

Research Highlight

Research Highlight

Novel electrolytic neodymium production process

Dimensionally stable anode for molten salt electrolysis of RE metals

CWRU: Rohan Akolkar elected senior member of National Academy of Inventors

CWRU: Scientists developing climate-friendly method to process ‘rare earth’ minerals; could make U.S. less reliant on foreign metals

Rohan Akolkar at Case Western Reserve University leads the CMI project "Development of a dimensionally stable anode for rare earth metal production via molten salt electrolysis (MSE)"

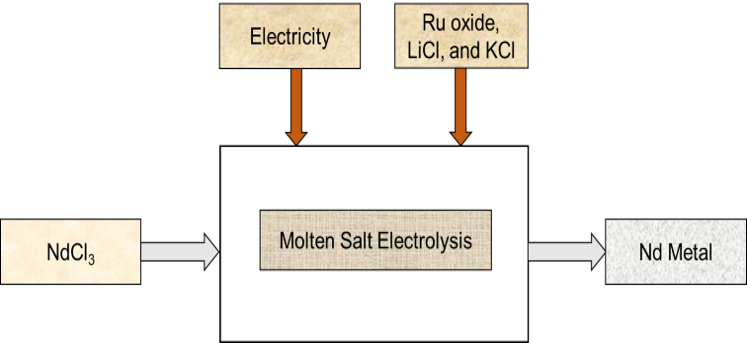

In this project, the team will develop a novel dimensionally stable anode (DSA) for high-temperature molten salt electrolysis of rare earths. Specifically, we will achieve reactor design and construction, modeling-guided process optimization, and lab-scale demonstration of the electrowinning of molten rare earth metals such as Nd and Ce. Proposed use of DSAs will eliminate CO2 and PFC generation during rare earth electrolysis, thereby enabling an environmentally-friendly and sustainable extraction process. The high surface area DSAs would reduce electrical energy consumption during electrolysis and enable stable and continuous rare earth metal production. Finally, the DSAs will enable improved process monitoring, which is advantageous for scale-up and automation.

The project team is featured in a CWRU Engineering video posted to social media July 5, 2023, including on LinkedIn

At the Electrochemical Materials Fabrication Laboratory at Case Western Reserve University, Critical Materials Institute (CMI) project lead Rohan Akolkar and his team are developing a sustainable electrolytic process for domestic production of critical metals. This work is supported by CMI and the Office of Energy Efficiency and Renewable Energy (EERE), U.S. Department of Energy.