News & Highlights

Preparation, evaluation and characterization of rare earth alloys directly from oxide intermediates

Research Highlight

Research Highlight

Preparation, evaluation and characterization of rare earth alloys directly from oxide intermediates

Research Highlight

Research Highlight

Preparation, evaluation and characterization of rare earth alloys directly from oxide intermediates

In the News

In the News

INL innovator wins Idaho Innovation award

P.K. Tripathy at Idaho National Laboratory leads the CMI project "Preparation, Evaluation and Characterization of Rare Earth Alloys Directly from Oxide Intermediates"

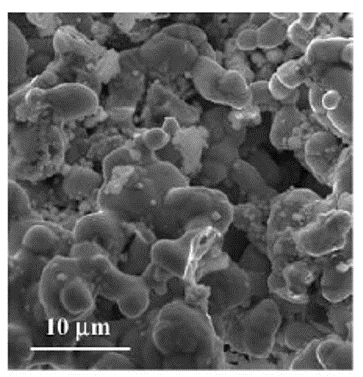

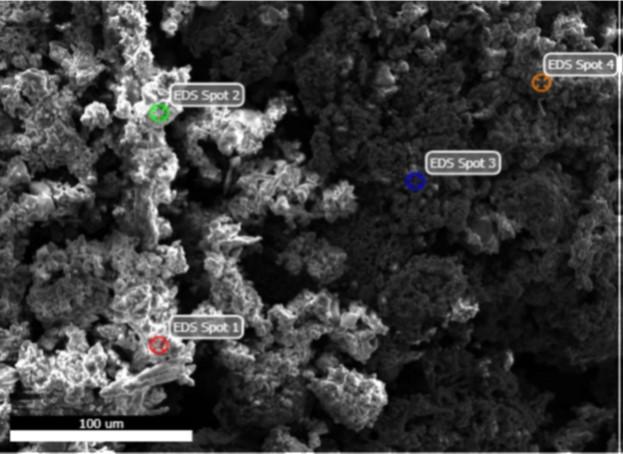

Rare earth alloys containing iron group metals (iron, cobalt and nickel) are technologically important materials for a variety of applications that include magnets, sensors and actuators. Commercially, these alloys are manufactured by a co-melting of process. The alloy constituents are prepared from their halide and/or oxide intermediates by a series or reduction-cum-refining steps. The proposed manufacturing process utilizes a novel molten salt electrochemical approach to prepare these alloys from their mixed oxide intermediates in just one operation. The overarching goal of the project is to develop a novel, generic, energy-efficient and inexpensive manufacturing process for rare earth-alloys.

Congratulations! INL innovator wins Idaho Innovation Award