ORNL has garnered 14 R&D 100 Awards, including R&D Researcher of the Year for Joshua New, highlighting the lab’s innovation across multiple categories.

The Critical Materials Innovation Hub, led by Ames National Laboratory, funded research at ORNL that led to the 2024 R&D 100 Award winner "High Lithium Capacity Sorbents for Direct Lithium Extraction Toward Increased Domestic Critical Mineral Supply Chain."

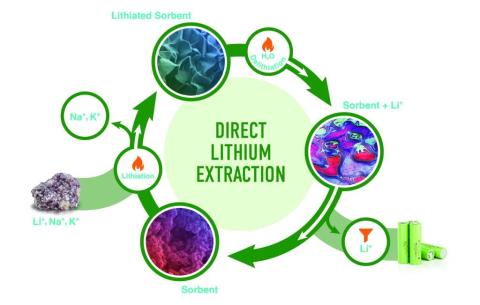

Lithium demand is increasing and better ways extracting lithium are needed. This technology, lithium carbonate or lithium hydroxide recovered from brines, clay minerals and recycled lithium-ion batteries, can improve the economics of lithium extraction for energy storage applications. The ORNL team has demonstrated that lanthanum manganese oxide and aluminum oxide are effective sorbents for selective extraction of lithium chloride or lithium sulfate from brines and recycled battery leachates, offering the possibility of effective application of lithium salts in lithium-ion batteries and leading to a fundamental shift in the lithium supply chain.

The main goal of this technology is to develop materials and processing technologies that enable significant new production of lithium from domestic resources by 2025. New lithium production must increase fourfold to meet demand and efficient methods for recovery, concentration and purification must be developed to lower costs, reduce the carbon footprint, conserve water resources and save energy. The ORNL team developed a series of lithium–aluminum-layered double hydroxide (LDH) chlorides (LDH-Cl) and iron-doped LDH, doped lithium manganese oxide and aluminum hydroxide sorbents to selectively extract more than 90% lithium over sodium and potassium in geothermal and oil field brines, clay minerals and recycled lithium-ion battery leachates. With its favorable environmental and economic performance, lithium sorption coupled with solvent extraction has great potential to enable the domestic production of battery lithium compounds.

This research was partly funded by DOE’s Critical Materials Innovation Hub in the Advanced Materials and Manufacturing Technologies Office and ReCell Center, Advanced Battery Recycling, Vehicle Technologies Office and Technology Commercialization Fund, Geothermal Technologies Office in the Office of Energy Efficiency and Renewable Energy.

Developers are Parans Paranthaman, Bruce A. Moyer, Jayanthi Kumar, Ramesh Bhave, Syed Islam, Barbara Evans, Saurabh Prakash Pethe and llja Popovs of ORNL; Bill Bourcier and Chris Camire of Mineral Selective Technologies; Aaron Celestian from the Natural History Museum of Los Angeles County; and Hood Whitson of Element3.

For complete information, link to the story on the ORNL website: ORNL wins 14 R&D 100 research awards