An international research team led by the University of Maryland has developed a novel elastocaloric cooling material that is highly efficient, eco-friendly and easily scaled-up for commercial use. The researchers new cooling material is a nickel-titanium alloy that was sculpted using additive technology (3-D printing). Their work is published in the November 29 issue of Science.

An international research team led by the University of Maryland has developed a novel elastocaloric cooling material that is highly efficient, eco-friendly and easily scaled-up for commercial use. The researchers new cooling material is a nickel-titanium alloy that was sculpted using additive technology (3-D printing). Their work is published in the November 29 issue of Science.

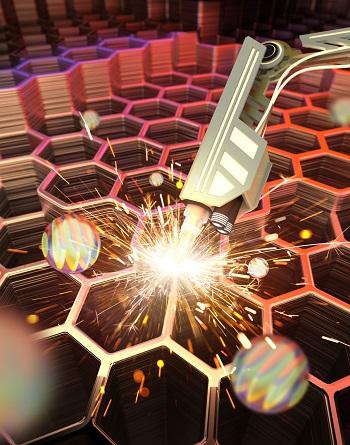

The material was developed using laser-engineered net shaping (LENS) equipment by researchers in Ames Laboratory's Division of Materials Sciences and Engineering.

News Link:

Published In:

Materials Sciences and Engineering