CMI researchers from Oak Ridge National Laboratory, Idaho National Laboratory and Marshallton conducted the research for this highlight.

Innovation

Improved light lanthanide separation using neutral extractant

Achievement

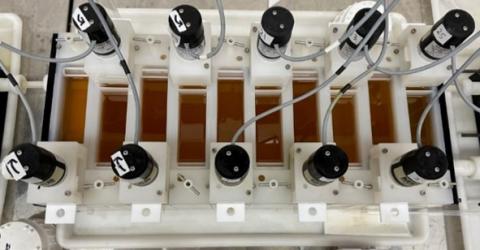

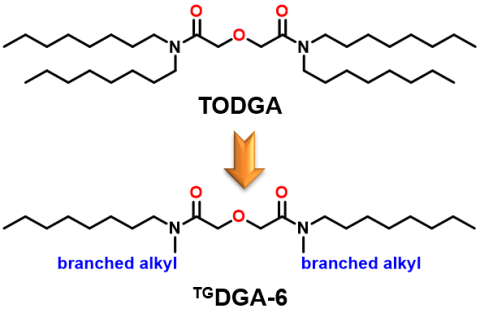

Successful run of a 32-stage counter-current mixer settler flowsheet using CMI’s novel technical-grade diglycolamide (TGDGA-6) extractant to separate La-Ce from Pr-Nd. Run completed flawlessly, data analysis in progress.

Significance and Impact

- Potential replacement of industry-standard REE extractant with more selective and efficient TGDGA-6 operating at high concentration and loading with good hydrodynamic properties from economical HCl feed solution.

- Potential reduction in footprint, CAPEX, and waste production.

- A different modifier at higher concentration (≥ 5 vol%) was found to avoid precipitation and emulsion problems encountered previously.

Hub Target Addressed

- Highly selective separation from complex sources

- Selective separation of adjacent Lns