This CMI research was conducted by researchers at Ames Laboratory and Oak Ridge National Laboratory.

Achievement

Designed and demonstrated a new reactor for producing rare earth magnet materials in high magnetic fields via hydrogenation-disproportionation-desorption-recombination (HDDR) chemistry.

Significance and impact

A new capability within CMI, enabling production of magnet powders and study of magnetic field on the associated chemical reactions and the resulting microstructure and magnetic properties.

Details and Next steps

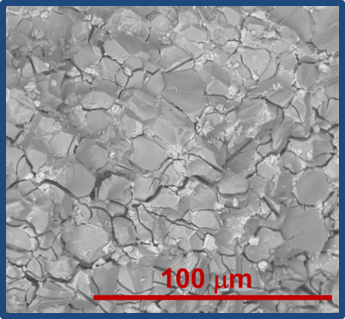

- HDDR is a commercial process for making Nd2Fe14B-based powders by reacting with hydrogen at high temperature then reforming. Application of a field during this process provides unique control.

- Development of this capability enables the CMI to study the role of magnetic fields in the HDDR process and optimize magnet powders in Year 8 and beyond.