CMI researchers from Oak Ridge national Laboratory and Purdue University conducted the research for this highlight.

Achievement

Lithium sorption from a leachate of domestic mine tailings improves economics and environmental impact.

Significance and impact

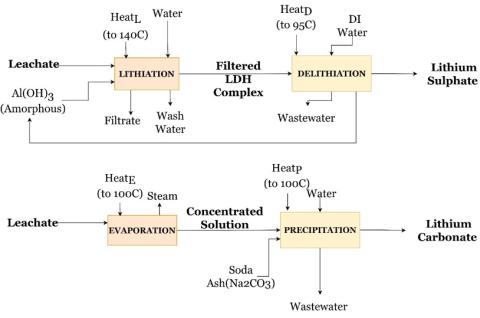

- Al(OH)3 sorbent recovers >93% of Li from an alkaline sulfate-bearing leachate of mine tailings.

- Delithiation using water and relithiation of Al(OH)3 demonstrate a complete separation cycle with circular economy.

- LCA shows 80% lower reagent consumption, 63% lower direct energy consumption, 73% lower global warming, and 73% lower fossil fuel depletion vs the standard evaporative method.

- Next steps involve testing potential extensions to Li recovery from minerals and to LIB recycle.

Hub Targets Addressed

Unlocking unconventional resources. Highly selective separation from complex sources.