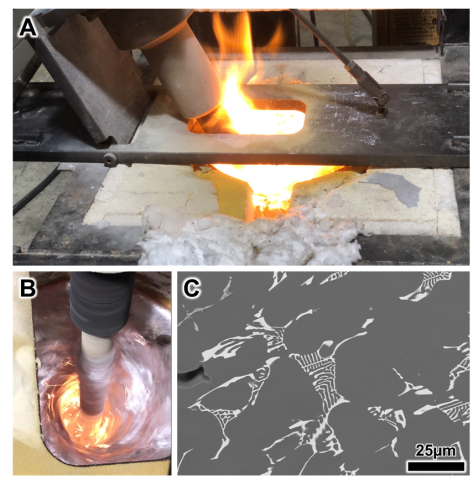

B: Kinetic stirring system agitating the mixture to promote reduction of the precursor compounds.

C: Backscattered electron micrograph of the resulting microstructure.

CMI researchers at Ames National Laboratory, Oak Ridge National Laboratory, University of Tennessee, Knoxville, and Eck Industries conducted the research for this highlight

Innovation

Process intensification of Al-Ce alloying by skipping prior Ce metallization step.

Achievement

Patent Issued on a new process for alloying Ce with Al using abundant REE mining by-products.

Significance and Impact

- Direct reduction of Ce oxide and carbonate offers the possibility of cost savings and lower energy consumption.

- Savings increase incentives to deploy Al-Ce alloys.

- Greater demand for Ce increases mining revenue for REE.

- Better mining economics diversifies supply of REE.

Hub Target Addressed

Diversifying the supply of REE by increasing the value of co-mined cerium. Conversion of critical materials into high-value end products. Industry adoption of REE technology.