CMI researchers at Ames National Laboratory conducted the research for this highlight

Innovation

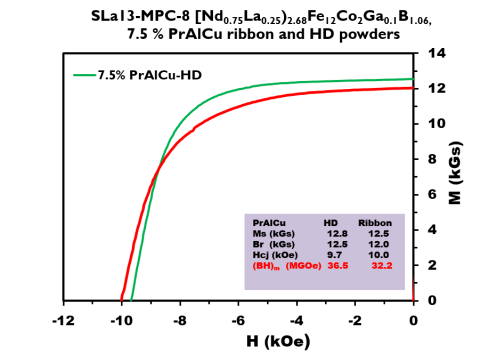

Improved the maximum energy product of the La-Nd based magnet (replaced 25% of Nd with La) to 36.5 MGOe.

Achievement

Increase over previous 32.4 MG-Oe record achieved by better grain boundary engineering - more uniformly distributed PrCuAl alloy on grain boundaries. Alloy hydrogen decrepitated before ball-milling, which gives finer powders, thereby finer distribution.

Significance and impact

This achievement proved that grain boundary engineering is an effective approach to improve magnet properties. It pointed the direction for this project to pursue.

Hub Target Addressed

Industrial option of CMI reduced-criticality clean energy technologies.