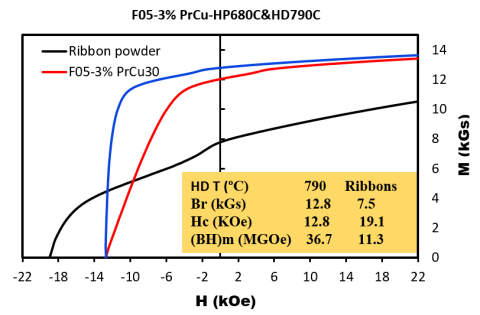

MH loops of the processed thin magnet (in plane)

CMI researchers at Ames Laboratory conducted the research for this highlight

Achievement

A novel bulk magnet fabrication process has been developed. Using hot-rolling processing, a thin bulk magnet with 37 MGOe at RT has been achieved, a significant improvement from 33 MGOe results reported six months ago.

Significance and impact

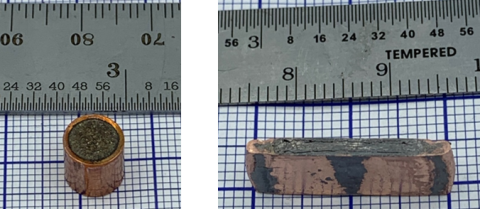

This manufacturing method was specifically developed for making small magnets: (1) simplified processing steps reduces the cost; (2) innovative use of copper deformable die enhance corrosion and magnetic properties; (3) the near-net-shape cross-section reduce part-failure rate and rare earth waste.

Next steps

- Design new composition to enhance texture.

- Scale-up for semi-continuous process

(Right): After process, thin bulk magnet enveloped by a copper shell providing mechanical support and corrosion protection.