In the quest for advanced vehicles with higher energy efficiency and ultra-low emissions, Oak Ridge National Laboratory researchers are accelerating a research engine that gives scientists and engineers an unprecedented view inside the atomic-level workings of combustion engines in real time.

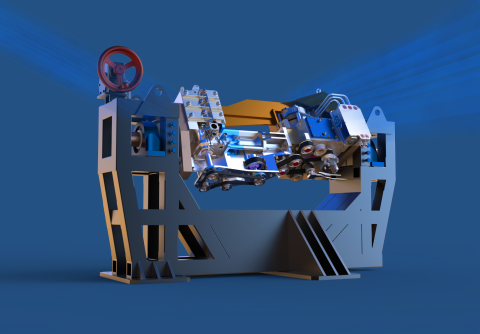

The new capability is an engine built specifically to run inside a neutron beam line. This neutronic engine provides a unique sample environment that allows investigation of structural changes in new alloys designed for the environment of a high-temperature, advanced combustion engine operating in realistic conditions.

ORNL first unveiled the capability in 2017, when researchers successfully evaluated a small, prototype engine with a cylinder head cast from a new high-temperature aluminum-cerium alloy created at the lab. The experiment was the world’s first in which a running engine was analyzed by neutron diffraction, using the VULCAN neutron diffractometer at the Department of Energy’s Spallation Neutron Source, or SNS, at ORNL.

The research on the aluminum-cerium alloy was sponsored by DOE’s Critical Materials Institute, which is supported by DOE EERE’s Advanced Manufacturing Office, along with Eck Industries, which helped develop and test the alloy and has licensed the material.