CMI researchers at Idaho National Laboratory conducted the research for this highlight

Achievement

- Higher cathode material recovery in various molten salt systems is enhanced in higher melting point salts.

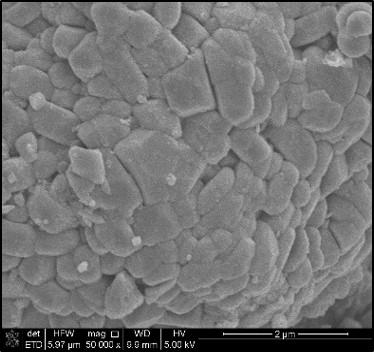

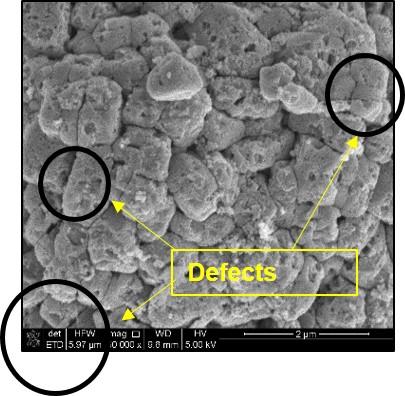

- Evaluated surface characteristics (e.g. composition, crystal structure, and particle size) of recycled active material after molten salt treatment.

Significance and impact

- Established the feasibility of using lithium molten salts to recover cathode materials.

- The LiOAc-LiNO3 system is preferred as it also does not introduce other cations.LiOAc-LiNO3 processing leads to uniform particle size (~20nm) and minimal destruction of crystal structure while decomposing PVDF binder.

- Pristine cathode electrode XRD spectra can be used to monitor structure changes after treatments and confirm components of cathode electrode.

Details and next steps

- Quantitatively determine the composition of recycled cathode materials: residues of PVDF, acetylene black, and active materials.

- Characterize recycled cathode materials via XRD and evaluate structure stability.