CMI researchers at Oak Ridge National Laboratory and the Florida Industrial and Phosphate Research Institute (FIPR Institute)conducted the activity for this highlight

Innovation

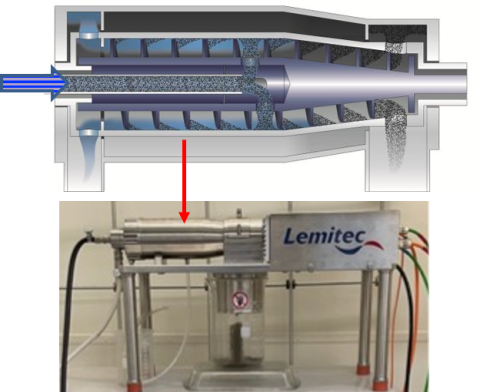

Continuous-flow decanter centrifuge effectively separates rare-earths (RE) containing solids and high-quality phosphoric acid (PA) for economic viability

Achievement

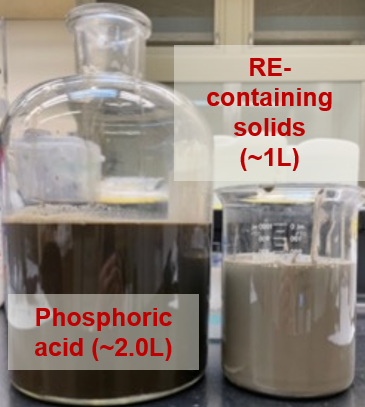

Effective solid/liquid separation was demonstrated using a decanter centrifuge. Mass balance over single-pass continuous-flow demonstrated over 95% recovery of PA liquid and over 87% recovery of RE-containing solids from a feed of 33.5 wt.% solids-containing PA sludge.

Significance and Impact

- Achievement ensures economic viability for RE recovery from PA sludge

- Expected to lead to an industrially relevant RE recovery process

- The separation process will be further optimized for longer operation and post-treatment for the recovery of phosphorus and RE

Hub Target Addressed

- Unlocking unconventional resources

- Recovery and conversion into high-value end products