CMI researchers at Ames Laboratory conducted the activity for this highlight

Innovation

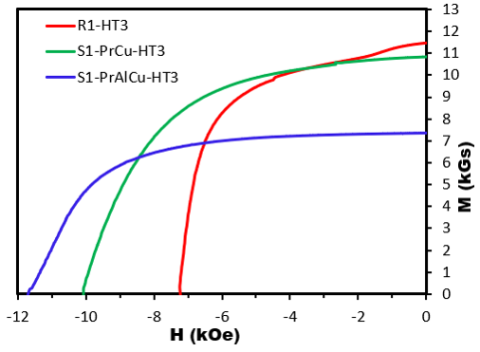

Coercivity of 12 kOe was achieved in the La-Nd based magnet via diffusion of sintering aid.

Achievement

Large coercivity will ensure resistance to demagnetization for the application of La-Nd magnets.

Significance and impact

- Helped advance coercivity beyond the previously reported 9 kOe by better utilization of the under-utilized anisotropy field.

- Diffusing non-magnetic Pr-Cu or Pr-Al-Cu into magnets enabled grain boundary engineering for improved coercivity in La-Nd magnet.

- Inspires search for a more effective coercivity enhancing material.

Hub Goal Addressed

Conversion into high value end products; Increase speed of discovery and integration.